Cold Feed Rubber Extruder

Precision Rubber Processing for the Modern Factory

Product Overview

Working Principle

Our Cold Feed Rubber Extruder utilizes advanced technology to process rubber compounds without pre-heating, ensuring superior quality and efficiency in rubber product manufacturing.

Key Features

- Precision temperature control

- High-efficiency screw design

- Robust construction for continuous operation

- User-friendly PLC control system

Applications

Ideal for processing a wide range of rubber products, including:

- Tires

- Hoses

- Cables

- Seals

- Shoe materials

Technical Specifications

| Model | Screw Diameter (mm) | L/D Ratio | Output (kg/h) | Motor Power (kW) | Max Screw Speed (rpm) | Barrel Type | Control System | Weight (kg) |

|---|---|---|---|---|---|---|---|---|

| DX-65 | 65 | 10~14 | 70~120 | 30~45 | 60~80 | Bimetallic/Alloy | PLC/Manual | 1800 |

| DX-90 | 90 | 10~14 | 150~250 | 55~75 | 60~80 | Bimetallic/Alloy | PLC/Manual | 3500 |

| DX-120 | 120 | 12~15 | 300~400 | 110~160 | 50~70 | Bimetallic/Alloy | PLC/Manual | 5000 |

| DX-150 | 150 | 12~15 | 500~700 | 160~220 | 50~70 | Bimetallic/Alloy | PLC/Manual | 6800 |

Custom sizes and specifications available upon request.

Structure & Features

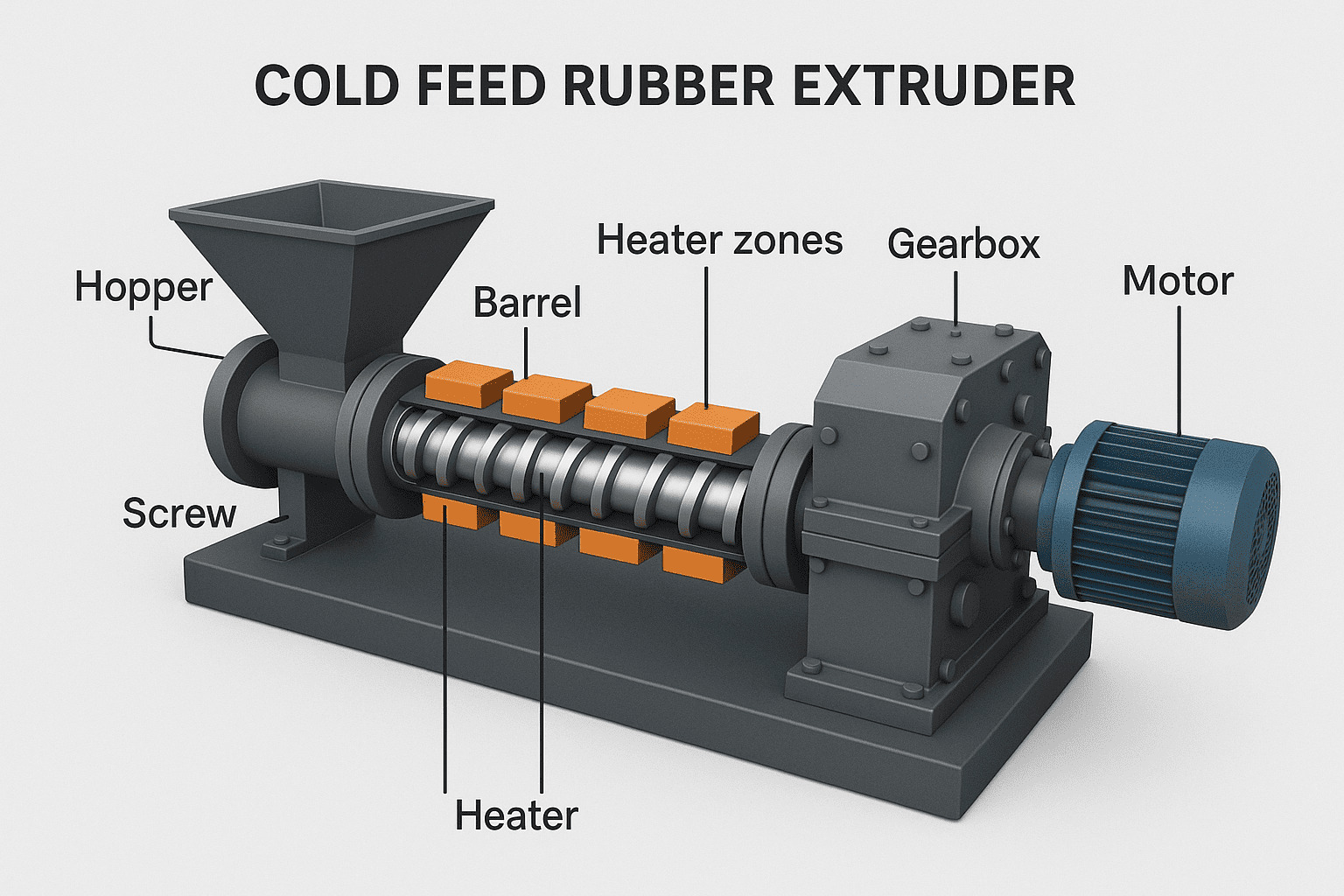

Key Components

- High-performance screw

- Precision-engineered barrel

- Advanced feeding system

- Efficient temperature control system

- Heavy-duty gearbox

Design Highlights

- Wear-resistant materials for extended lifespan

- Easy maintenance design for quick servicing

- Modular construction for future upgrades

Working Principle & Process Flow

1

Material Feeding

Cold rubber compound is fed into the extruder

2

Mixing & Plasticizing

Material is mixed and heated by screw rotation

3

Extrusion

Homogenized rubber is extruded through the die

Cold feeding improves product quality and energy efficiency by eliminating pre-heating steps.

Quality Control & Certification

Quality Inspection Process

- Hardening treatment verification

- Surface roughness measurement

- Concentricity testing

- Performance trials under various conditions

Certifications

- ISO 9001:2015 certified

- Adherence to industry-specific standards

Industrial Applications & Case Studies

Tire Manufacturing

Improved efficiency in tire tread extrusion process.

Automotive Parts

Precision extrusion for complex automotive seals.

Conveyor Belts

High-volume production of durable conveyor belts.