Many people think injection molding is just melting plastic and pushing it into a mold. Simple, right? From my experience, it's not that easy. It's a delicate balance of heat, pressure, and timing. Get one thing wrong, and your perfect part becomes scrap.

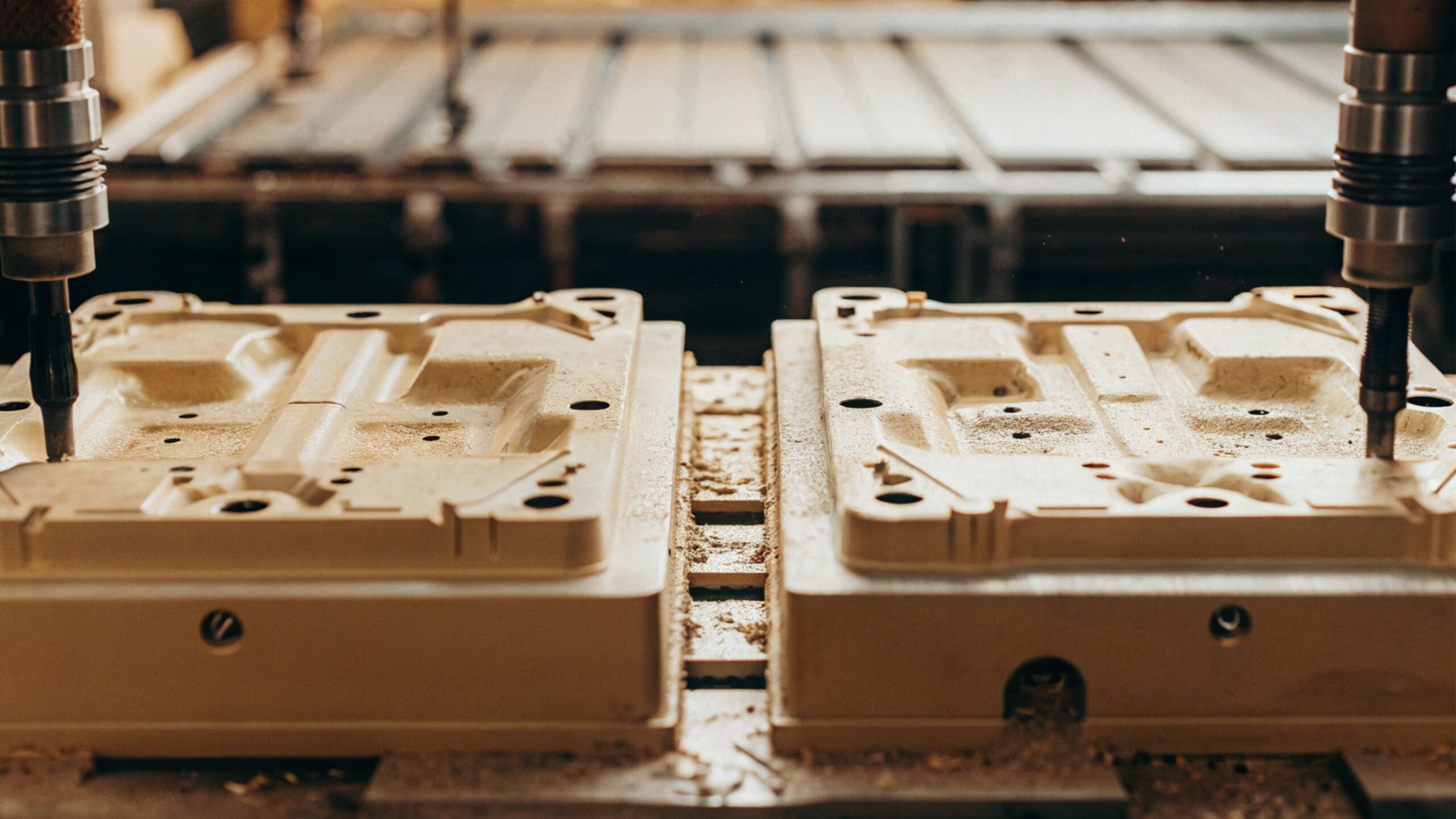

A plastic injection mold works by creating a hollow cavity in the shape of the desired part. Molten plastic is forcefully injected into this cavity under high pressure. Once inside, the plastic cools and solidifies, taking the exact shape of the mold, then opens and the solidified plastic part is ejected.

I've seen this process thousands of times. The mold itself is like a puzzle made of steel. It has two main halves that clamp together very tightly. When they close, they form a space inside that looks exactly like the part you want to make. Think of it as a sophisticated cookie cutter, but for plastic. The mold is bolted onto the injection molding machine. This machine then heats up plastic pellets until they are liquid. Then, with great force, it pushes this liquid plastic into the mold.

This seems simple, but my customers often face problems. For example, if a part has both thick and thin sections, it's a real challenge. If you push the plastic too hard to fill the thin parts, the thick parts might get "flash" (extra plastic where it shouldn't be). Or the part might have hidden stress inside, making it weak. The real trick is to find the perfect speed, temperature, and pressure for each section of the mold. It is like tuning a musical instrument. Every part of the process must work together.

What is the Injection Molding Process Step by Step?

My customers often ask for a simple breakdown. They want to know what happens from start to finish. I always tell them it's a series of carefully timed steps.

The injection molding process involves six key steps: clamping the mold, injecting molten plastic, holding pressure to pack the part, cooling the plastic, opening the mold, and ejecting the finished part. Each stage requires precise control of temperature, pressure, and time to ensure consistent part quality.

Let me walk you through it as I explain it to new operators on the factory floor.

First, the machine grabs the mold halves. This is the clamping stage. The two halves of the mold are pressed together with a lot of force by the machine's clamping unit. This force must be strong enough to keep the mold closed when the hot plastic is injected. Imagine trying to hold two heavy books together while you push liquid in between them; you need a strong grip.

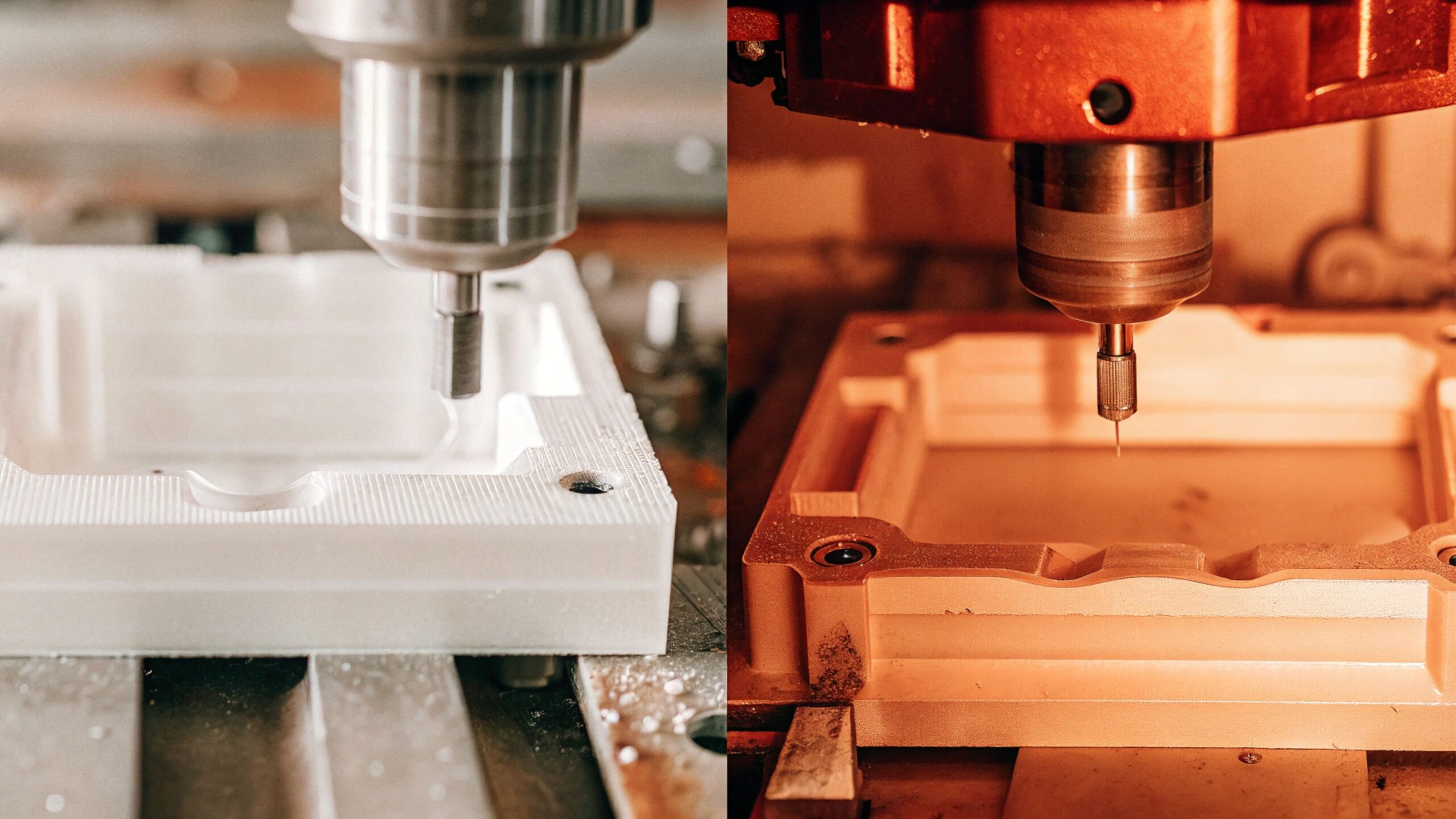

Second is the injection stage. The screw inside the machine moves forward very fast. This pushes the hot, melted plastic, which we call "melt," from the barrel into the closed mold cavity. This happens at high pressure and controlled speed. It's important to get the right speed. Too fast, and the plastic might burn or create air traps. Too slow, and it might cool before filling the mold completely.

Third is the holding (or packing) stage. Once the mold cavity is almost full, the machine reduces the injection speed but keeps the pressure on. This "holding pressure" pushes a little more plastic into the mold. This makes up for any shrinkage as the plastic cools. It also helps to pack the plastic tightly into every corner of the mold. This stage is crucial for avoiding sinks (dents) in your finished part.

Fourth is the cooling stage. After the plastic completely fills the mold and is packed, the gates (small openings where plastic entered the mold) freeze. The machine then holds the mold closed while water or oil flows through cooling channels inside the mold. This cools the plastic down until it solidifies. The cooling time depends on the plastic material and the part's thickness. During this cooling, the screw also pulls back, gathering more plastic for the next shot.

Fifth is the mold opening stage. Once the part is solid enough, the clamping unit opens the mold halves. They separate, revealing the finished part inside.

Finally, the ejection stage. Small pins, called ejector pins, push the cool, solid part out of the mold cavity. The part then falls into a bin, or a robot arm picks it up. After the part is removed, the mold closes again, ready for the next cycle to begin. Each of these steps must be precise. If one step is off, the final part will be bad.

What is the Basic Principle of Injection Molding?

People often overthink the science. I tell them to just focus on the core idea.

The basic principle of injection molding is to transform solid plastic pellets into a molten state and then force this molten plastic into a closed mold cavity. Once the plastic cools and solidifies within the mold, it takes on the exact shape of the cavity, creating a precisely formed plastic part.

From my perspective, it’s about control. You take plastic, heat it up to a liquid, push it where you want it to go, and then cool it down quickly so it holds its shape. But the "control" part is what makes it so complex and powerful.

Here is a simple breakdown of the main ideas behind this process:

| Principle | What it means | Why it's important to me and my customers |

|---|---|---|

| Heating | Converting solid plastic pellets into a homogeneous, molten fluid. | If uneven, parts will be weak or discolored. |

| Injection | Forcing the molten plastic into the mold cavity under high velocity and pressure. | Ensures complete filling of the mold, especially complex shapes. |

| Cooling | Rapidly removing heat from the molten plastic inside the mold. | Determines part solidification and cycle time; too fast or too slow causes issues. |

| Shaping | The mold cavity defines the final geometry of the part. | Mold exactness means part exactness. |

| Repetition | The process is designed to repeat thousands of times to make identical parts. | Cost-effective for mass production; consistency is crucial. |

Think of it like pouring jelly into a mold and letting it set. You heat the jelly, pour it, let it chill, and then you have a perfect shape. The difference with injection molding is the immense pressure to ensure the plastic fills every tiny detail, and the precise control over temperature at every stage. This allows us to make millions of identical parts, from tiny LEGO bricks to large car components, with high accuracy. This is why Dongxu focuses on making high-performance screw and barrel assemblies – they are essential for achieving that precise heating and injection.

How Long Does a Plastic Injection Mold Last?

This is a common question. Everyone wants to know their investment will last. The answer is, it depends!

The lifespan of a plastic injection mold varies greatly, ranging from tens of thousands to millions of cycles, depending on factors such as mold material, complexity, maintenance, and the type of plastic being molded. High-quality steel tools designed for high-volume production can last for 10+ years.

I've seen molds last for only a few months, and others still running strong after a decade. It's like asking how long a car lasts. It depends on how you drive it and how you take care of it.

Here are the main things that affect how long a mold will run:

| Factor | Impact on Mold Lifespan | My Advice to Customers |

|---|---|---|

| Mold Material | Softer aluminum molds for prototyping (thousands of cycles). Hardened steel molds (P20, H13) for production (millions of cycles). | Invest in quality steel for high-volume jobs. It pays off in the long run. |

| Part Material | Abrasive plastics like glass-filled nylon wear down molds faster. Corrosive plastics like PVC attack mold surfaces. | If running tough materials, ask for hardened inserts or plated molds. This extends mold life significantly. |

| Maintenance | Regular cleaning, lubrication, and repair of wear parts extend life. Poor maintenance leads to early failure. | Implement a strict preventative maintenance schedule. It's cheaper than emergency repairs or mold replacement. |

| Design | Complex molds with many moving parts or thin sections can wear out faster. Simple, robust designs last longer. | Design for manufacturability. Simpler designs are not only cheaper to build but also last longer on the machine. |

| Process | Over-packing or using excessive injection pressure can stress the mold, causing wear or cracking. | Optimize your molding parameters. Running the machine too aggressively will shorten the mold's life. |

| Cycle Rate | Faster cycles mean more stresses and impacts in a shorter time, leading to faster wear. | Balance cycle time with mold longevity. Sometimes a slightly longer cycle is better for the mold’s welfare. |

For example, when a client comes to me needing to mold a part with glass-filled plastic, I immediately emphasize the need for a wear-resistant screw and barrel from Dongxu, but also tell them they need a mold made from harder, tougher steel or with special coatings. The plastic itself acts like sandpaper on the mold over time. Conversely, a simple part made from plain polypropylene might use a less expensive mold material and still last for millions of cycles.

What is the Process of PVC Injection Molding?

PVC is common, but it's different. Many problems happen when people treat PVC like any other plastic.

The process of PVC (Polyvinyl Chloride) injection molding requires specialized considerations due to PVC's thermal sensitivity and corrosive nature. It involves using lower processing temperatures, careful control of residence time to prevent degradation, and specialized corrosion-resistant screw and barrel assemblies, along with nickel-plated or stainless steel molds, to produce parts.

PVC is tricky. It's a fantastic material for many things, but it hates heat, and it can be very corrosive. I've helped many customers switch from other plastics to PVC or troubleshoot their PVC lines. The main challenges are preventing degradation and managing corrosion.

Here's how PVC molding is different:

| Aspect | Standard Plastic Molding | PVC Injection Molding | Dongxu's Role |

|---|---|---|---|

| Material Degradation | Tolerant to a wider range of temperatures and residence times. | Highly sensitive to heat. Degrades easily, releasing hydrochloric acid gas (HCl), which is corrosive and toxic. | Our specialist screws reduce shear heat. |

| Processing Temperatures | Often run at higher temperatures (e.g., 200-300°C). | Lower temperatures (typically 170-200°C). Minimal shear heating. | We offer precision temperature control on our barrels. |

| Machine Components (Screw/Barrel) | Standard Nitrided steel often suffices. | Corrosion-resistant materials are essential. Bi-metallic barrels (like ours at Dongxu), chrome-plated or electroless nickel-plated screws. Avoid dead spots. | This is our specialty! We engineer for durability. |

| Mold Material | Standard tool steel (P20, H13). | Corrosion-resistant steel (e.g., 420 stainless steel) or plated molds (nickel plating). | N/A (mold specific) |

| Machine Purging | Can often purge with the same material. | Requires special purging compounds. Important to purge completely before and after PVC runs to prevent buildup and acid attack. | N/A (process specific) |

| Screw Design | Standard compression ratios. | Screws with lower compression ratios and often no mixing elements (which can create shear heat and dead spots). Optimized for gentle handling. | Our custom screws are designed for PVC. |

| Ventilation | Standard factory ventilation. | Excellent ventilation is needed to remove HCl fumes, especially around the mold and barrel. | N/A (factory environment) |

When working with PVC, I stress the need for specialized equipment. Standard screws and barrels will quickly corrode and fail. At Dongxu, we have specific designs and material treatments for PVC applications, like our bi-metallic barrels and specialized screw coatings. These ensure that the part quality is high and your equipment lasts longer. Always remember: for PVC, keep it cool, keep it moving, and keep it clean.

Conclusion

Injection molding is a precise dance of physics and engineering. Understanding how molds work, the step-by-step process, its basic principles, mold lifespan, and material specifics like PVC, empowers you to optimize production. From choosing the right screw and barrel by Dongxu to meticulous process control, every detail counts towards perfect plastic parts.