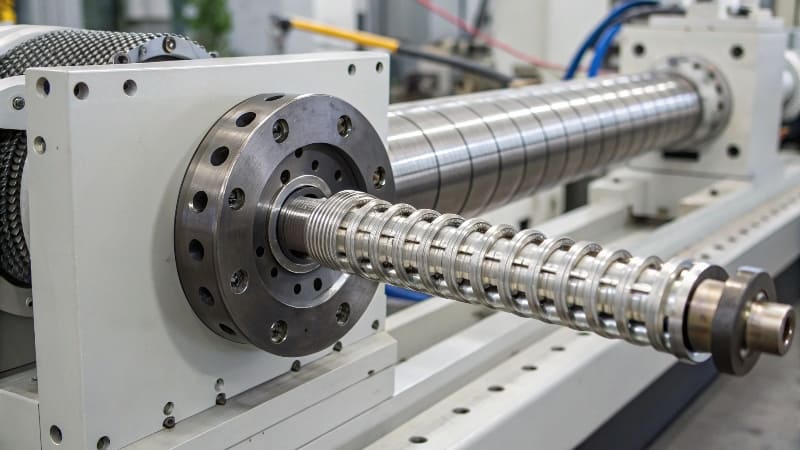

Screw Barrel for Extruder Machine

2025-08-10

From thousands of hours observing and optimizing extruder lines, I've seen that many people focus on the plastic pellets going into the machine and the product coming out. But the real magic happens inside, with the "marriage" between the screw and the barrel. This pair is crucial for good production and product quality.

The screw barrel1 is the heart of an extruder machine2, consisting of a rotating screw precisely fitted inside a stationary barrel. This assembly performs the critical functions of conveying, melting, mixing, and homogenizing plastic materials3 under controlled temperature and pressure, transforming raw pellets into a consistent melt ready for shaping.

Most people think a screw just pushes material forward. But it's much more than that. This partnership is where the magic (or trouble) happens: the material is moved, melted, mixed, and made uniform under careful control of temperature and pressure.

For example, trying to run a very abrasive, glass-filled plastic in a screw and barrel that aren't hardened? You will see them wear out very fast. This leads to material getting stuck, bad mixing, and uneven flow. I have seen cases where simply upgrading to a bi-metallic barrel4 and a very wear-resistant screw immediately fixed long-standing quality problems and made the equipment last much longer. This upgrade paid for itself many times over.

On the other hand, an aggressive screw design5 meant for high-output plastics might damage a sensitive PVC material if they are not matched correctly. It is not just about the parts by themselves, but how they work together synergistically. They must be carefully chosen for the specific plastic and the output you want. This "marriage" controls everything from the quality of the melted plastic to how much energy is used and the final product's properties. It is the unappreciated hero, or villain, of the extrusion process.

What is an Extruder Barrel?

I often get asked this by those new to the field. I explain it simply, like a specialized pipe.

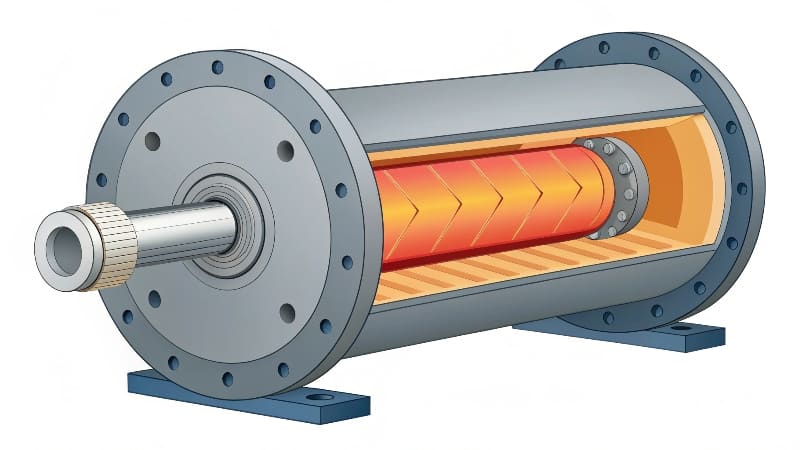

An extruder barrel is a thick-walled cylindrical chamber within an extruder machine that houses the rotating screw. It provides a confined space for plastic material to be heated, conveyed forward, and subjected to pressure and shear forces, facilitating melting and homogenization before extrusion.

Think of the barrel as the cooking pot in our extrusion kitchen. It holds the material and provides the heat. But it's not just any pot.

Here are the key points I share with my clients about the extruder barrel:

| Feature | Description | Why it matters to me and my customers |

|---|---|---|

| Material & Construction | Barrels are typically made from specialized steel alloys, often with wear-resistant liners (bi-metallic barrels, like those Dongxu makes, have a harder inner layer). | Durability against wear and corrosion: A high-quality barrel resists abrasive materials (like glass-filled plastics) and corrosive ones (like PVC), ensuring longer lifespan and consistent internal diameter. |

| Heating Zones | The barrel is equipped with multiple heating elements (band heaters) along its length, divided into zones to allow for precise temperature control6. | Controlled melting: Each zone can be set to a specific temperature profile (e.g., warmer at the start, hotter in the middle, cooler at the end). This ensures gradual, even melting and prevents material degradation. |

| Internal Surface | The inner surface of the barrel is precisely machined and often honed. In many cases, it may have grooves or smooth walls depending on the specific application and screw design. | Efficient material conveyance and shear: The interaction between the screw flights and the barrel wall is critical for moving the material forward and generating necessary shear for melting and mixing. |

| Length-to-Diameter (L/D) Ratio | The ratio of the barrel's length to its internal diameter. Typically ranges from 20:1 to 40:1, varying based on the application. | Processing capability: A longer L/D ratio7 allows more time for melting, mixing, and degassing, which is crucial for complex or sensitive materials. Shorter L/D for basic polymers or high output. |

| Vent Ports | Some barrels feature vent ports8 (openings) along their length, used to remove volatile gases or moisture from the melt. | Improved product quality: Essential for preventing air bubbles, surface defects, and enhancing material properties, especially for hygroscopic plastics. |

When I consult with clients, I emphasize that the barrel is far more than just a tube. Its construction directly impacts energy efficiency, melt quality, and how long the entire extrusion line runs without problems. A poorly chosen or worn barrel leads to increased downtime and inconsistent product quality, costing a lot of money in the long run. At Dongxu, we invest heavily in barrel technology because we know it's a foundation for our customers' productivity.

What Type of Screw is Used in Extrusion?

This is where the real customization happens. There's no one-size-fits-all.

The type of screw used in extrusion machines varies significantly based on the polymer being processed, desired output, and specific mixing requirements. Common screw designs include single screws with various zones (feed, compression, metering), and specialized barrier or mixing screws for enhanced performance.

Just like different chefs need different stirring spoons, different plastics need different screw designs. The screw is the material's journey manager.

Here's a breakdown of common screw types and their purpose:

| Screw Type | Primary Function | Ideal Material/Application | My Experience/Insight |

|---|---|---|---|

| Standard Three-Zone Screw | Most common. Divides into: Feed Zone (conveys pellets), Compression Zone (melts plastic and builds pressure), Metering Zone (pumps homogeneous melt at consistent rate). | General purpose thermoplastics (PE, PP, PS, ABS) for profiles, sheet, film. | This is the workhorse. Getting the lengths and depths of these zones right is key. Too short a compression zone, and you won't fully melt the plastic. Too long, and you might over-shear it. It's a delicate balance. |

| Barrier Screw | Features an extra flight that separates the molten plastic from the solid plastic. This improves melting efficiency and reduces melt temperature fluctuations. | Polyolefins (PE, PP), particularly for film and blow molding where melt homogeneity and temperature control are critical. | My customers using these screws often report better product clarity and fewer gels or unmelted particles. It's a great upgrade for higher quality demands. |

| Mixing Screw | Incorporates specialized mixing elements (e.g., Maddock, Dulmage, pineapple mixers) to enhance distributive (spreading components evenly) and dispersive (breaking down agglomerates) mixing. | Highly filled polymers (e.g., glass fiber compounds), masterbatches, and applications requiring excellent color or additive dispersion. | Crucial for composite materials. Without proper mixing, you'll see streaking or weak spots. I've engineered many Dongxu screws with custom mixing sections to solve specific customer challenges. |

| Vented Screw | Designed to work with vented barrels (see above). Features a decompression zone where trapped gases can escape, followed by a re-compression zone. | Hygroscopic plastics (e.g., PET, Nylon, PC) that absorb moisture, or plastics with volatile components. | Essential for perfectly clear and strong parts. Moisture in these plastics means bubbles or degradation. It saves a lot of money on pre-drying. |

| Low Shear Screw | Gentle profile designed to minimize shear heating9 and maintain material integrity. | Heat-sensitive materials (PVC, CPVC), foamed plastics, and certain filled compounds where integrity is paramount. | This is vital for PVC. Too much shear, and PVC degrades, releasing corrosive gases that damage your equipment. Our Dongxu screws for PVC are specifically engineered to be low shear. |

Selecting the right screw is one of the most important decisions in extrusion. It determines your throughput, melt quality, energy consumption, and even the lifespan of your barrel. At Dongxu, we excel at designing custom screws to match specific polymer properties and application needs. We don’t just supply parts; we engineer productivity.

What is the Screw Profile for an Extruder?

When I talk about "screw profile," I'm referring to the specific geometry of the screw along its length. It's not just a big corkscrew.

The screw profile for an extruder refers to the specific design and dimensions of the screw's flight depth10, lead, and helix angle across its different zones (feed, compression, metering, and sometimes mixing or venting sections). This profile dictates how material is conveyed, melted, mixed, and pressurized within the barrel.

The screw profile is the blueprint of material transformation. It's where we fine-tune the process for a specific plastic.

Here’s a breakdown of the critical elements of a screw profile:

| Element | Description | Function in Extrusion |

|---|---|---|

| Flight/Channel Depth | The distance from the root (core) of the screw to the top of the flight. This depth varies along the screw's length, being deepest in the feed zone and shallowest in the metering zone. | Conveyance & Compression: Deeper flights in the feed zone pull pellets efficiently. Decreasing depth (compression) squeezes and melts the plastic, building pressure. |

| Flight Width & Clearance | The width of the flight land (the top surface contacting the barrel wall) and the small gap (clearance) between the flight and the barrel. | Shear & Pumping Efficiency: Proper clearance allows some melt to circulate (drag flow), generating shear for melting. Too much clearance reduces pumping efficiency. |

| Lead & Helix Angle | Lead: The axial distance advanced by one full turn of the flight. Helix Angle: The angle the flight makes with the axis of the screw. | Conveying Action: These angles determine how efficiently the screw pushes the material forward. Optimized for different material friction properties. |

| Number of Flights |

Understanding the screw barrel is essential for optimizing extrusion processes and improving product quality. ↩

Explore the workings of an extruder machine to grasp its role in plastic processing and production. ↩

Understanding homogenization can help improve the quality of your extruded products. ↩

Explore the advantages of bi-metallic barrels for durability and performance in extrusion. ↩

Understanding screw design can lead to better performance and efficiency in extrusion. ↩

Temperature control is crucial for quality; learn how it's managed in extrusion. ↩

Learn how the L/D ratio affects processing capabilities and product quality in extrusion. ↩

Discover how vent ports improve product quality by removing gases during extrusion. ↩

Understanding shear heating can help you maintain material integrity during processing. ↩

Discover the impact of flight depth on material conveyance and melting in extrusion. ↩