How to Choose a Suitable Screw for Your Injection Molding Machine?

2025-08-09

Choosing the right screw for your injection molding machine can make or break your production. Get it wrong, and you face poor product quality, slow cycles, and constant breakdowns.

Selecting the correct screw for an injection molding machine depends on the specific plastic material, desired melt quality, and production goals. Different polymers require varied screw designs (e.g., L/D ratio, compression ratio, mixing sections) to ensure optimal melting, mixing, and injection performance, preventing material degradation and ensuring consistent part quality.

When customers ask me about screw size, I always start with their machine's specifications and the parts they are making. You need to look at two main things: the screw diameter and the shot weight1. The screw diameter2 usually matches the barrel diameter. This is fixed for your machine. But the shot weight is about your part.

You see, each screw size has a maximum shot volume3 it can deliver. If your part is too big for the screw, you need a different screw or a different machine. Also, the screw diameter affects how fast the plastic melts. A bigger screw handles more plastic but might take longer to heat it all up evenly. A smaller screw heats plastic faster but can't push as much.

Here’s how I often explain it to my clients, thinking about the balance:

| Factor | Too Small Screw | Too Large Screw | Ideal Screw |

|---|---|---|---|

| Shot Volume | Insufficient for part, requires multiple shots (short shots) | Can lead to material degradation due to long residence time | Matches part volume, single shot |

| Melt Quality | Faster melting, but potential for uneven mixing | Slower melting, potential for material burning | Consistent melting and good mixing |

| Machine Fit | May not be efficient, high wear on screw | Excessive back pressure, machine strain | Optimized for machine capacity and output |

| Energy | Higher energy per unit due to short cycles | Wasted energy due to inefficient melting | Efficient energy use for melting |

It's a balance. You want the screw to be big enough for your part but not so big that plastic sits in the barrel for too long. If plastic sits too long, it can burn or degrade, ruining your parts. I always tell my clients to use the smallest screw that can handle their largest shot weight. This helps save material and energy.

What type injection molding machine screw is it?

Many clients ask me if there's just one type of screw. No. There are different designs for different needs.

Injection molding machine screws are typically classified by their design features, which are optimized for specific plastic materials and processes. Common types include general purpose screws, barrier screws4 for better melting and separation of solids, mixing screws5 (e.g., Maddock, Dulmage) for enhanced homogeneity, and specialized screws for abrasive or corrosive materials, like bi-metallic or nitride-coated screws.

-

Consider the material you are running:

| Screw Type | Best For | Key Feature | Dongxu's Insight |

|---|---|---|---|

| General Purpose | PP, PE, PS, ABS (non-filled) | Basic design, good balance for many materials | Good for most standard jobs, but not optimized for extremes. |

| Barrier Screw | HDPE, LLDPE, parts requiring high melt quality6 | Separates solid and melt, improves consistency | Excellent for reducing unmelted particles, improves part aesthetics. |

| Mixing Screw | Color compounding, filled materials, recycled plastics | Special mixing elements (e.g., Maddock, Dulmage) | Ensures uniform color and additive dispersion, critical for quality. |

| Vented Screw | Materials sensitive to moisture | Section for degassing/moisture removal | Essential for materials like Nylon or PC to prevent bubbling. |

| Corrosion-Resistant | PVC, Halogenated polymers, Flame Retardants | Special alloys (e.g., Hastelloy, bi-metallic liner) | My company specializes in these to extend lifespan. |

| Wear-Resistant | Glass-filled, mineral-filled, abrasive compounds | Hardened steel, bi-metallic, powder alloy materials | Crucial for longevity with tough materials, reduces downtime. |

There is no "universal" screw. Anyone who tells you there is, is wrong. It's about matching the tool to the job. Customization is key to getting the best output.

What are the three zones of injection molding screws?

Every good screw has three main zones. These zones work together to turn cold plastic pellets into hot, melted plastic that can be injected.

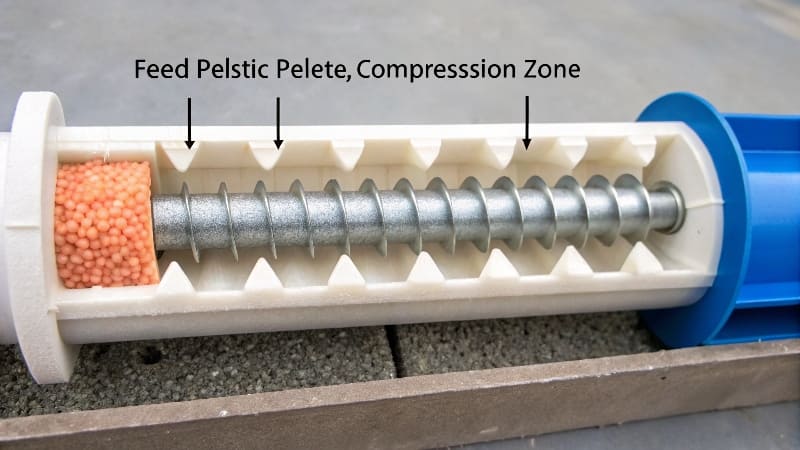

Injection molding screws are designed with three primary functional zones: the feed zone7, where plastic pellets are introduced and conveyed; the compression (or transition) zone, where the plastic melts as it is compressed and heated; and the metering zone8, which homogenizes the melt and builds pressure for injection. Each zone serves a specific purpose in the melting and conveying process.

When I explain this to customers, I often compare it to how a baker kneads dough. Each stage has a purpose.

The feed zone is where the plastic pellets drop into the barrel from the hopper. The flights (the helical ridges on the screw) convey these pellets forward. The depth of the screw channels here is usually constant and deepest. The main job is to pull the cold plastic into the barrel and towards the heater bands. If this zone is too short or designed incorrectly, you might not get enough plastic moving forward.

Next comes the compression zone9, also called the transition zone. This is where the magic happens. The screw channel depth gets shallower here. As the screw turns, it squeezes the plastic. This compression, along with heat from the barrel heaters and the friction from the screw turning, melts the plastic. This zone is critical. If it's too aggressive, you can stress the plastic. If it's not aggressive enough, you'll have unmelted pellets. This is where the "compression ratio10" of the screw comes into play – the ratio of the flight depth in the feed zone to the metering zone. A higher compression ratio means more shear and heat imparted to the plastic. Different materials need different compression ratios. For example, rigid PVC needs a lower compression ratio than HDPE.

Finally, we have the metering zone. In this zone, the screw channel depth becomes constant again, and it's the shallowest part. By now, most of the plastic should be melted. This zone's job is to homogenize the melt (make it uniform) and build up the final pressure needed for injection. It also acts as a pump, pushing the consistent melt to the front of the screw. A longer metering zone can improve melt uniformity but also increases shear heat and residence time, which might be bad for sensitive materials.

Understanding these zones is key to troubleshooting common problems like unmelted plastic, black specks, or inconsistent shot weights. Each zone must be optimized for the specific plastic being processed.

What is the correct name for the important screw in the injection molding process?

Sometimes, people just call it "the screw." But in our industry, we have a more precise name for it.

The critical component responsible for conveying, melting, mixing, and plasticizing material in an injection molding machine is correctly known as the "plasticizing screw11" or "reciprocating screw12." It performs the crucial function of conditioning the raw plastic pellets into a homogeneous melt ready for injection into the mold.

When I'm talking to engineers or purchasing managers, I usually call it the "plasticizing screw." This name describes its main function: taking solid plastic and making it plastic-like, or "plasticizing" it. It's not just a conveyor belt; it’s a processor.

It is also often referred to as a "reciprocating screw" because it not only rotates to melt and mix the plastic but also moves forward and backward (reciprocates) to inject the molten plastic into the mold and then retract to accumulate the next shot. This back-and-forth movement is what gives the "injection" part of injection molding its name.

This single component has to handle high temperatures, high pressures, and corrosive or abrasive materials. It's a complex piece of engineering. That’s why we at Dongxu put so much effort into its design, material selection, and precision manufacturing. We know that the performance of this one screw directly impacts your product quality and your bottom line.

Conclusion

Understanding your injection molding machine screw is essential for success. Choosing the right size, type, and understanding its working zones will lead to better parts, less waste, and more productive operation. Don't underestimate this vital component. 1shot weight is the most key points for your production

Exploring shot weight helps in selecting the right screw size for efficient production and material usage. ↩

Understanding screw diameter is crucial for optimizing machine performance and ensuring quality in injection molding. ↩

Learn about shot volume to ensure your machine can handle the required part sizes effectively. ↩

Barrier screws enhance melt quality; exploring their benefits can improve your production efficiency. ↩

Mixing screws ensure uniformity; understanding their function can enhance product quality. ↩

Melt quality is vital for product consistency; understanding it can enhance your production outcomes. ↩

Understanding the feed zone's role can help troubleshoot issues related to material feeding. ↩

The metering zone ensures uniform melt; understanding it can improve shot consistency. ↩

The compression zone is critical for melting; learn how it impacts the overall process. ↩

The compression ratio affects melting efficiency; knowing it can help optimize your screw design. ↩

The plasticizing screw is key to the injection process; knowing its role can enhance your operations. ↩

Understanding the distinction helps in selecting the right screw for your injection molding needs. ↩