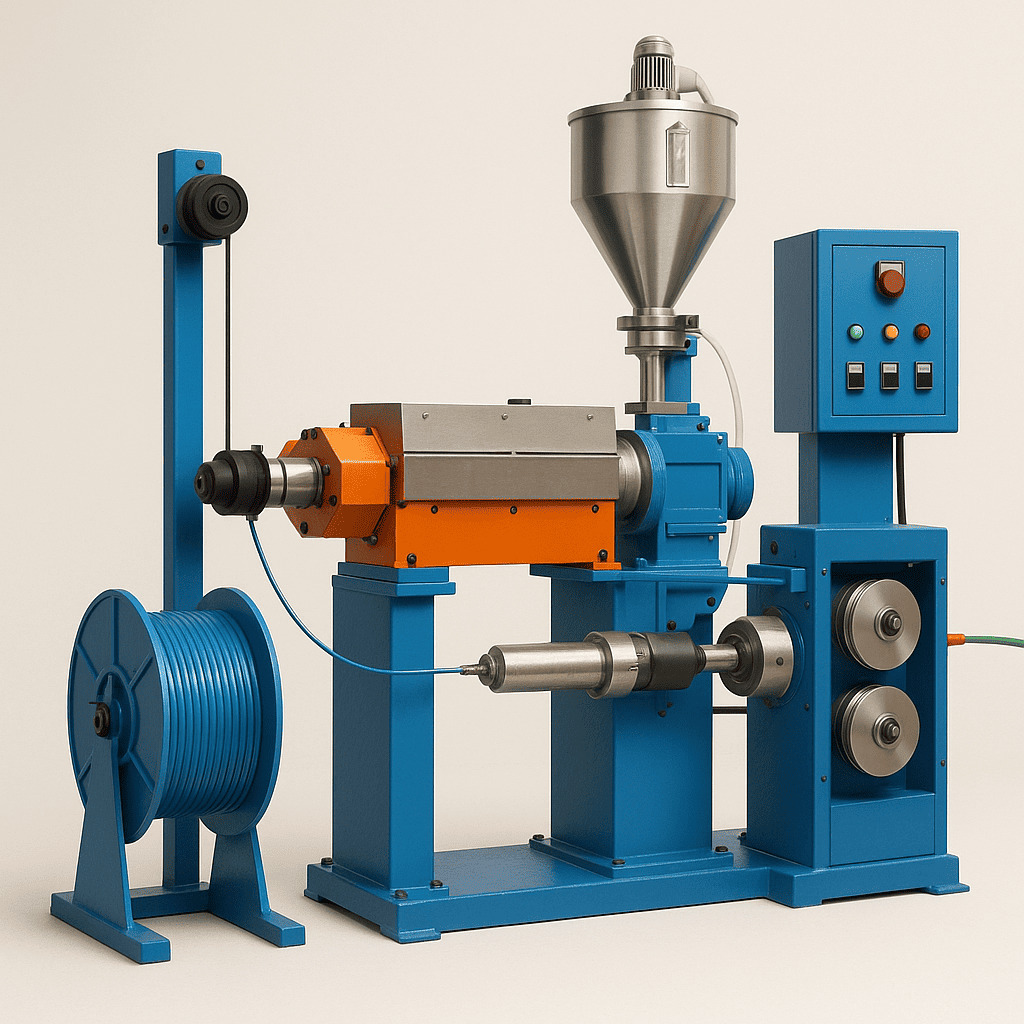

Wire & Cable Extruder

High-performance extruding system for continuous insulation, sheathing, and jacketing of electrical wires and cables.

Product Overview

A high-performance extruding system designed specifically for the continuous insulation, sheathing, and jacketing of electrical wires and cables, supporting a wide range of materials such as PVC, PE, XLPE, and TPE.

Reliable, energy efficient, and flexible for diverse wire & cable production lines.

Main Features & Advantages

Precise Temperature Control

Multiple temperature control zones for stable extrusion process

High-quality Components

Premium alloy screw & barrel ensuring extended service life

Modular Design

Flexible configuration for various cable production needs

Technical Specifications

| Specification | Parameter |

|---|---|

| Screw Diameter | 45 / 65 / 90 mm |

| L/D Ratio | 25:1, 30:1, 33:1 |

| Output | 50–500 kg/h |

| Main Motor Power | 15–110 kW |

Construction & Components

1. Feeder System

Automatic material feeding system

2. Main Extruder

Core processing unit

3. Crosshead/Die

Precision extrusion forming

4. Cooling System

Temperature control and stabilization

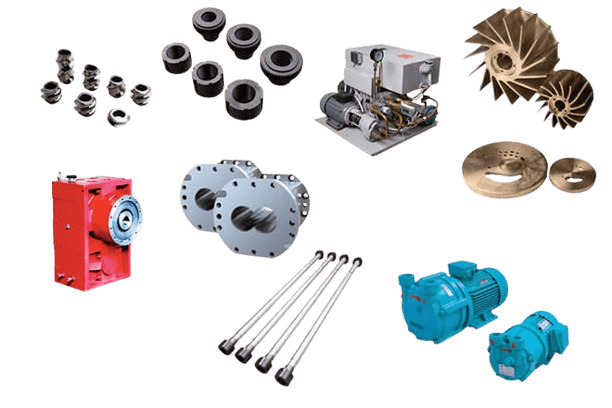

Leading Manufacturer of Plastic & Rubber Processing Solutions

Specializing in screw barrels and complete equipment solutions for the plastics and rubber processing industry.

20+ Years Experience

Our Core Products

Screw Barrels

- • Single/Twin Screw Barrels

- • Planetary Screw Barrels

- • Custom Solutions

Complete Equipment

- • Plastic Processing Lines

- • Rubber Processing Lines

- • Steel Pipe Coating Lines

Precision Parts

- • Automotive Components

- • Marine Equipment Parts

- • Aviation Components

Application Areas

Textile Machinery

Specialized components for textile processing equipment

Food Processing

Food-grade machinery components

Environmental

Sustainable processing solutions

Custom Solutions

Tailored to specific industry needs

Ready to Discuss Your Project?

Our technical team is ready to assist with your specific requirements